CXDT: Expert in Carbon Steel Fasteners

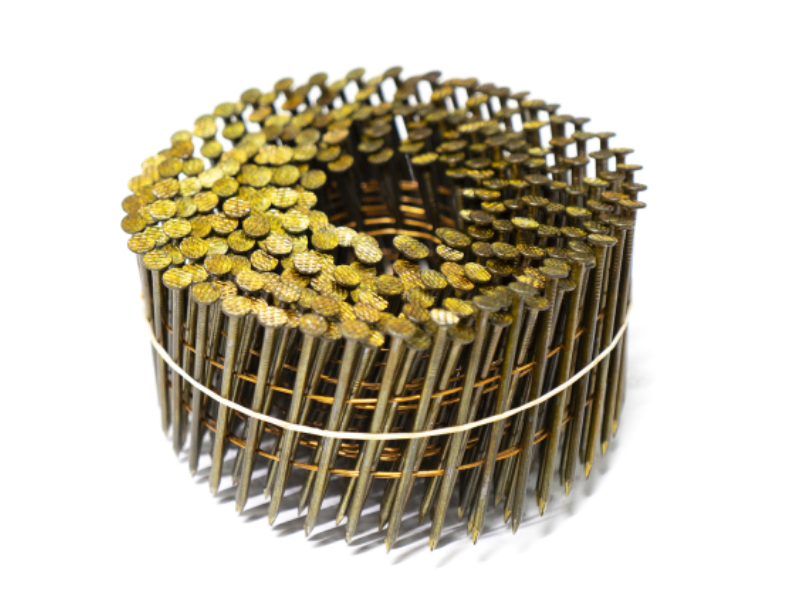

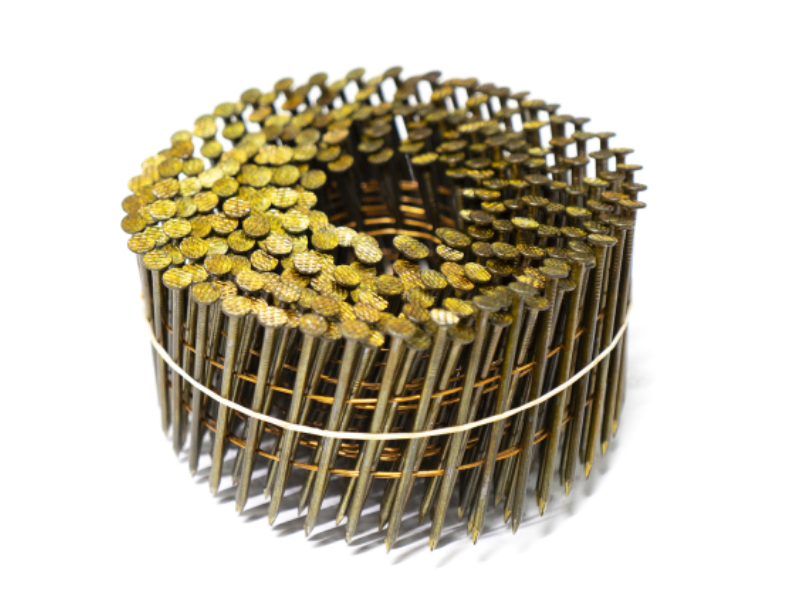

In the field of industrial consumables, carbon steel fasteners have always played an irreplaceable role as a fundamental but crucial building auxiliary material. As a leading force in the field of hardware manufacturing, CXDT has established a benchmark image for precision manufacturing in China in the global market with its excellent craftsmanship inheritance and innovative research and development capabilities. We not only provide standardized industrial nail solutions, but also strive to create personalized customized services for global customers, building a full industry chain advantage from raw material procurement to terminal delivery.

As a leading fastener production base in the Yangtze River Delta region of China, CXDT has invested in introducing Germany's fully automatic cold heading forming system and Japan's heat treatment process line to build an intelligent production matrix with a monthly production capacity of over 2000 tons. Every steel nail certified by ISO9001 quality management system undergoes 12 precision processes from wire screening to surface treatment. The independently developed zinc nickel alloy coating technology improves the corrosion resistance of the product by 300% and successfully passes the ASTM B117 salt spray test, providing reliable protection for harsh environments such as marine equipment and outdoor buildings.

In response to the demand for bulk procurement, we have innovatively launched a tiered pricing model: single orders of 5 tons can enjoy exclusive logistics channels, and orders of 20 tons or more will be equipped with a full quality traceability system. In a recent cooperation case with a large infrastructure group in the Middle East, we developed explosion-proof alloy nails for their oil and gas pipeline projects. By optimizing the stress distribution design of the nail body, the shear strength was increased to 1800N/mm ², successfully helping the project pass the API SPEC 5CT certification.

Based on the advantages of the Yangtze River Delta industrial cluster, we have built a vertical supply chain system from Baosteel's high-quality wire supply to smart warehousing at ports. Realize visual control of the entire order process through the ERP system, ensuring a response speed of 72 hours for urgent orders. The newly put into operation intelligent stereoscopic warehouse in 2023 adopts AGV unmanned handling system, which improves the warehouse turnover efficiency by 40% and reduces the wrong delivery rate to below 0.02%.

Adhering to the concept of "precision manufacturing, global connectivity", we have provided over 120 customized solutions to customers in 36 countries and regions. Our engineering and technical team can provide full cycle services from material selection to application testing, whether it is the special thread fastening requirements of the Dubai World Expo venue or the nails used in ultra-low temperature environments at the Nordic Polar Research Station. Click on the official website's online inquiry system to instantly obtain exclusive steel nail solutions and real-time quotation lists.